|

5083 MARINE ALLOY - PLASTIC FREE BOAT

Please use our A-Z INDEX to navigate this site or return HOME

|

|||

|

PLASTIC FREE SHIP - In the quest for zero pollution shipping, this design takes a lot of beating. We have a zero single use plastic policy, backed by a recycling pledge, typically by pyrolysis technology. But, prefer to source products free of plastic at the outset.

Many metals can be recycled over and over again, such as aluminium and steel. But they are not a renewable resource. Meaning that they cannot be naturally replaced. Typically, nonrenewable resources are found in the ground, such as rocks, fossil fuels and minerals. Once they are depleted, they are gone forever. Timber, is a good example of a construction material that is a renewable resource. But when oak trees were used to build the galleons of old, whole countries had their forests depleted. Including the UK. That was in the days before responsibly managed replanting schemes.

High value, and infinitely recyclable aluminum is a material tailor-made for a more circular and sustainable economy. Provided that we learn how to better recover the metal from used objects, such as soft drink cans, aluminum windows and vehicle engine parts. 5083 marine grade alloy, does not corrode in seawater. Boats and ships made of this material will have a very long service life - and may then be recycled. In volume, copper is the third most recycled metal after iron and aluminium.

5083 aluminium alloy is an aluminium alloy with magnesium and traces of manganese and chromium. It is highly resistant to attack by seawater and industrial chemicals.

Sometimes, solutions are staring us in the face. Remember our old chum John Harrison, with his marine chronometer, and the Board of Longitude, who could not see the wood for the trees. They were literally holding the solution in their hands, but refused to accept it.

Aluminium alloys used in shipbuilding are easier to recycle than cans recovered from domestic waste. They are thus a preferred marine construction material, as with steel, for building larger ships. Both being relatively harmless to the marine environment, even in a total loss situation.

It's a common sight, that everyone takes for granted, without realising the implications. Today, even fishing workboats are now made of GRP, when they used to be steel. Aluminium doesn't get so much of a look in, where it is more expensive. If these abandoned boats had been made of wood or alloy, they would have been recovered for recycling. GRP boats should be tagged, with an end of life cost for responsible disposal. Illegal disposal, by deliberate sinking, would have to carry hefty fines, to cover the cost of salvage and responsible disposal.

COMPARE

STEEL RECYCLING

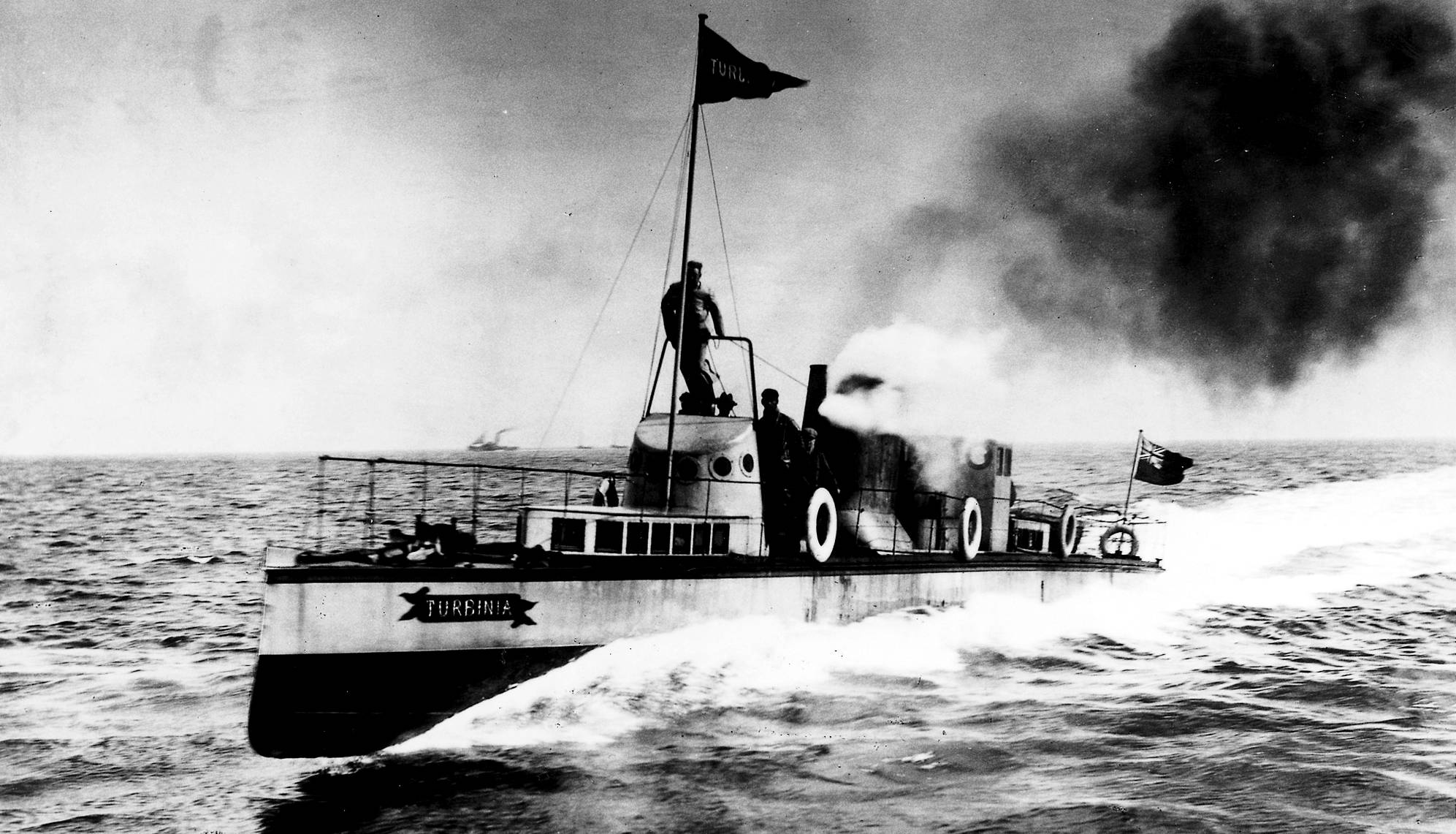

[LEFT] TURBINIA - Parsons' ship turned up unannounced at the Navy Review for Queen Victoria's Diamond Jubilee at Spithead, on 26 June 1897, in front of the Prince of Wales, Lords of the Admiralty and foreign dignitaries. As an audacious publicity stunt, Turbinia, which was much faster than any ship at the time, raced between the two lines of navy ships and steamed up and down in front of the crowd and Princes, while easily evading a Navy picket boat that tried to pursue her, almost swamping it with her wake. The first turbine-powered merchant vessel, the Clyde steamer 'TS King Edward,' followed in 1901. The Admiralty confirmed in 1905 that all future Royal Navy vessels were to be turbine-powered, and in 1906 the first turbine-powered battleship, the revolutionary 'HMS Dreadnought,' was launched. Now imagine a hydrogen powered ship, outperforming a diesel bunkered vessel is such an audacious display.

[RIGHT] MARINE CHRONOMETER - The Board of Longitude, famously, charged with finding a solution to the navigation problem, failed to recognize when they had found what they were looking for. This is a frequent problem for experts who only want to receive solutions that fit within their understanding of current knowledge - not accepting anything that does not conform. They would rather deny a solution. Some more practical sailors thought otherwise, gratefully accepting John Harrison's timepieces as essential navigation aids. This included the Royal Navy's Captain James Cook (HMS Endeavour, Discovery & Resolution) and Captain Robert Fitzroy (HMS Beagle) 1763-1779. Modern day 'Board's of Longitude,' are seen in technology grant decision makers all over the world. They fight shy of presented solutions, they want alternative solutions. It keeps them searching for their Unicorns and creates new knowledge. Such policies are though climate unfriendly in a race against time. A climate friendly policy is one that gets results more quickly and with the minimum of administration, such that the Harisson's and Ericsson's of today might surface sooner. Regardless, we keep on and on issuing calls for proposals, that extends the time to a solution that we can ill afford. Better, perhaps, to support the bird in the hand. If development takes longer and costs more, that extra money also equals a bigger carbon footprint, in the form of the taxpayer who earned the money for the grant-maker's to spend.

ALUMINIUM

The U.S. produces more recycled aluminum than any single country other than China.

Increasing aluminum recycling translates to less energy used and a lower carbon impact.

For example, in the aluminum beverage can market, each percentage increase in the end-of-life recycling rate reduces the carbon intensity of aluminum beverage can production by 1.02 kg CO2 equivalent per 1,000 cans.

|

|||

|

ZEWT ALORS - The solar and wind powered 'Elizabeth Swann' will feature solar collectors and wind energy harvesting apparatus in an advanced configuration. Her hull configuration is ideal for mass hydrogen storage tanks, offering ranges of up to 4,000nm.

LEO PERRIN'S - Blog about the technology used to construct the Elizabeth Swann 1:20 scale model. In this case a basic introduction to welding steel and aluminium. The solar panel array drive-shaft assembly needs six precision welds. Leo will be presenting on more subjects, as the hydrogen project continues.

|

|||

|

ALUMINIUM

RECYCLING

Brazil recycles 98.2% of its aluminium can production, equivalent to 14.7 billion beverage cans per year, ranking first in the world, more than Japan's 82.5% recovery rate. Brazil has topped the aluminium can recycling charts eight years in a row. The recycling rate for aluminium beverage cans in the European Union, United Kingdom, Switzerland, Norway and Iceland stands at 73%.

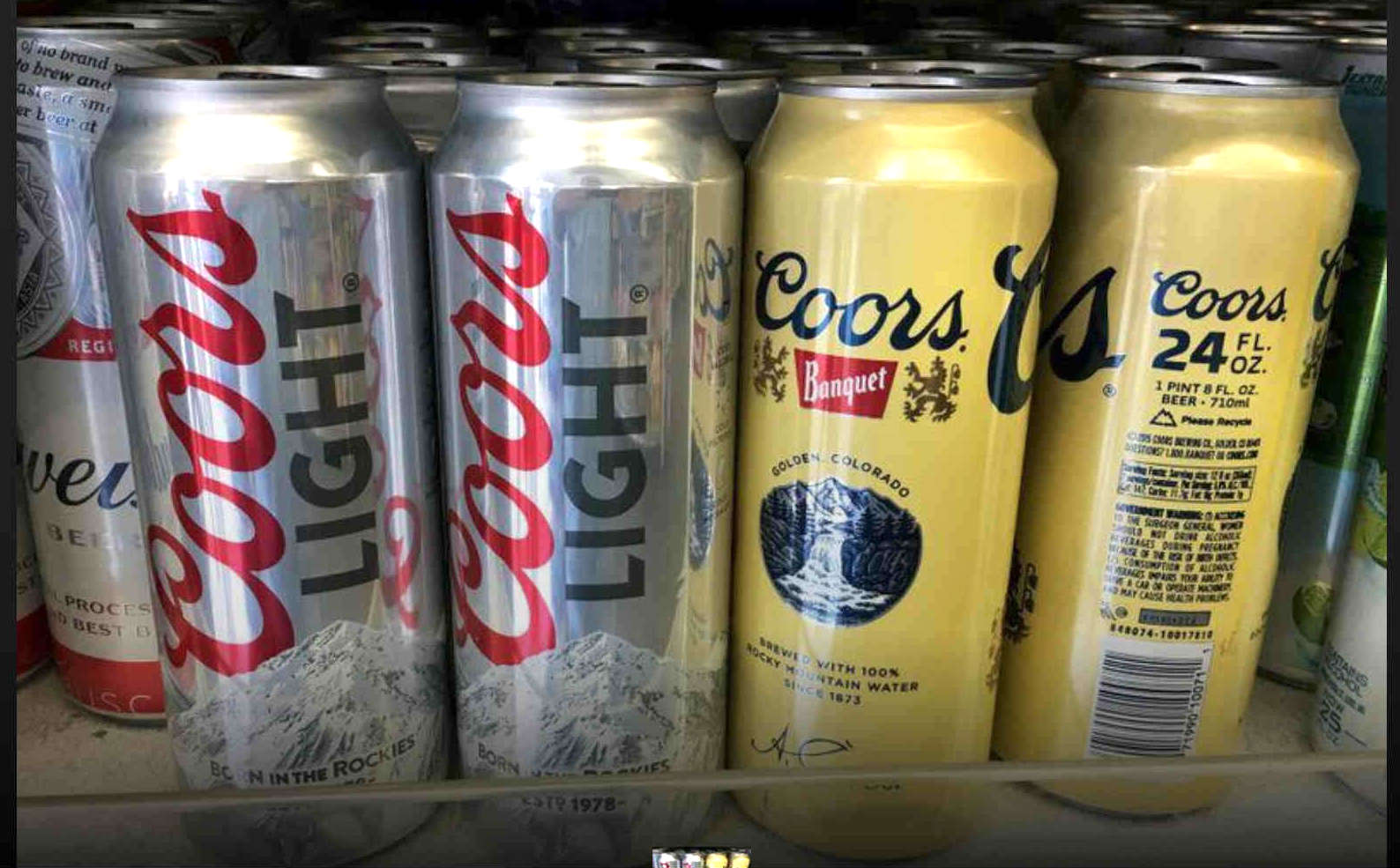

The aluminium can is the poster child for recyclability dating back to those first Coors’ two-piece cans. When Coors introduced the first all-aluminium beverage can in 1959, it offered one cent on every can returned.

The power-intensive smelting process means that aluminium accounts for around 2% of all global greenhouse gas emissions with much variability depending on energy source.

- Recycling is a critical part of the modern aluminum business. Making recycled aluminum only takes around 5% of the energy needed to make new aluminum — reducing carbon emissions and saving money for businesses and end consumers.

▲ In most industrial markets like automotive and building, recycling rates for aluminum exceed 90%.

▲

Industry recycling efforts in the U.S. save more than 90 million barrels of oil equivalent each year.

LINKS & REFERENCE

https://designedconscious.com/plastics-in-the-ocean/sustainability-news-stories/is-fiberglass-recyclable-who-is-recycling-fiberglass/

|

|||

|

Please use our A-Z INDEX to navigate this site or return HOME

This website is Copyright © 2024 Jameson Hunter Ltd

|