|

HYDROGEN - HIGH CAPACITY STORAGE TANKS

Please use our A-Z INDEX to navigate this site or return HOME

|

|

NEW BOY ON THE BLOCK - In this CAD end elevation, it is possible to see how the simple trimaran hull design lends itself to our purpose, providing evidence that hydrogen vessels might ply our oceans in the quest for zero emission waterborne transport. But like all technical challenges, until somebody does it, the trophy remains up for grabs. Nobody has yet crossed a major ocean using only hydrogen as a stored fuel. In our view, the design challenges are containable. Currently, the most developed and widely used method to store hydrogen is by compression. We are focusing on this method. Please note, the latest Elizabeth Swann design is copyright © from June 2021, with all rights reserved.

The unique design of the Elizabeth Swann's hulls gives us the opportunity to incorporate massive hydrogen storage tanks, in proportion to the vessel's displacement. But even the USA's Jumbo tanks are not voluminous enough for shipping. That said, no other ship design that we know of, may be adapted quite so readily, as we write.

The proposal was 1st floated on this site in July 2021, amid heat waves, water, and food shortages hitting headlines across the globe. It is surely time for change and we must rise to the challenge, in a race against time. How long it might take to develop an efficient and safe solution is impossible to estimate, with so many variables. Including the materials used for cylinders and if we are to give way to liquid hydrogen, for larger ships. Despite the conversion efficiency losses.

Is it possible? This is one of the questions that most naval architects are struggling with, hence this example 'call for proposals' under Horizon Europe: ZEWT HORIZON-CL5-2021-D5-01-07 June-September 2021, for mass hydrogen storage. Fortunately, a lot of work has been done on this already, for transporting hydrogen using tube tankers.

A conventional ship mono-hull would present us with an extremely difficult design challenge, thus the EU's 'Waterborne' partnership are looking at ammonia based fuel cells and ammonia for internal combustion engines to replace diesel oil. But, there are ways to get around design problems. For now, we think we have the solution at hand. Don't forget our old chum John Harrison, with his marine chronometer, and the Board of Longitude, who could not see the wood for the trees. They were literally holding the solution in their hands, but refused to accept it.

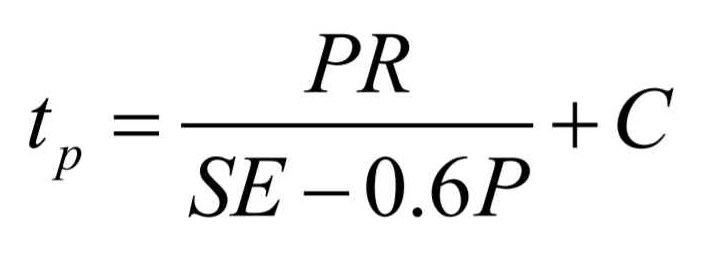

FORMULA - For calculating wall thickness of a cylinder. The variables being the material used, operating pressure and temperature. Plus a safety margin. Clearly then, the choice of material is a major design consideration, to be weighed up against cost. Without taking cost into consideration, it is a toss up between aluminium and titanium. Both offering significant weight savings.

PRACTICAL LONG RANGE CRUISER

To be a truly practical long range cruiser, we need to store enough hydrogen to cross the Atlantic with a bit more in reserve. So, we've allowed for a range of 4,000 nautical miles, giving us 500nm in hand (3,500 actual). For which at normal, moderate cruise speeds we'll need roughly 30kWh for around 26 days of run time. That means we'll need to carry 624kg of hydrogen (1kg=33.6kWh), allowing a further 10% margin for safety.

We are not keen on using expensive Type III-IV high pressure cylinders as in the automotive industry, though (modified) T1 containers used to bulk transport hydrogen by truck, are an option.

Type 1 all metal hydrogen storage tanks are the least expensive to manufacture. They are fabricated as a

rolled metal

cylinder (aluminium, stainless & other high tensile steels),

seam-welded, and can be

very large. These are generally the heaviest Hydrogen Storage Tanks and operate at lower pressures than the other types of

containers being looked at.

For that reason, and conscious of the cost, we are even considering titanium

for structural longevity, and corrosion resistance in harsh

environments.

We are looking for a good compromise, reduced weight, at a sensible price, while still offering the storage capacity for blue water voyages.

As and when ammonia technology improves, the same tanks used for hydrogen storage, could be used to store ammonia in many of its forms, as a potential range improver. It is not practical to produce ammonia onboard. Liquid hydrogen is another option, bringing with it a different set of problems, and raising the price bar.

CHEMICAL TANKER - Nice rig! But these tube trailers in T316 stainless steel are only pressure tested to 45psi. These might be suitable for ammonia. But here we are considering hydrogen.

Five different types of storage tanks have been developed and are used to store hydrogen at increased pressures (from 10–20

[1450-2900psi] to 70 MPa [10,000psi]). These tank types are generally denoted by Roman numerals, I, II, III, IV and V based on the complexity of the storage tank.

The largest tank volumes for gaseous hydrogen transport (road haulage) are currently 26 cubic meters.

The MPa, the rather ungainly 'Megapascal Pressure Unit' is an

abbreviation of x 1,000,000 multiple of the pascal, which is the SI unit for pressure.

TUBE

TRAILER - 13 jumbo tubes

= Water Volume: 1011 cubic feet (77.769 ft3 per cylinder) Standard Cubic

Feet (SCF)

In the marine environment and with such enormous volumes, we are seeking a practical solution. Automobile tanks typically operate at between 350-700 bar (5,000 - 10,000 psi). We'd be happier operating at around 70 bars (1,000 psi). If we need more energy to allow for the inefficiencies in the conversion chain,* we might go to 100, or even 140 bars (2,000 psi). Bearing in mind that increased compression, makes hydrogen as a fuel proportionally more expensive.

The formula we favour allows for high power to the propellers of 300kW for short durations with a relatively small fuel cell, say 60kW. We'd allow for 400kWh in battery storage, around the same as 10 x BMW i3 power packs (2240kg). Our preferred configuration will give us 21,168kWh in energy storage, from hydrogen in gaseous form. This can be doubled, by increasing tank pressure to 2,000psi, to yield a theoretical 42,336kWh power bank.

In this example, we are not including the energy generated from the onboard solar panels (55-70kW)*. Though, if we were to add that to the daytime running hours, there would be a significant performance increase - and the vessel would still qualify as ZEWT.

If, as it appears from these basic calculations, we can conquer the Atlantic with hydrogen, a Cross Channel Ferry is more of a walk in the park. Our problem is access to finance, made all the more acute in that we are a not-for-profit organization, developing IP for dissemination, simply to cover our costs. Our agenda being to conserve the ocean and cool our climate. Partnerships such as the 'Waterborne' big players, have access to €millions of euros of funding. It is truly a David and Goliath situation, that we hope to overcome with an appealing design, to help us attract philanthropic corporations - who like us - want to see alternative solutions ply the waves.

TOYOTA MIRAI - This famous OEM has gone all out to produce a technological marvel. Without innovators and engineers, we'd not be able to develop these works of art. Without our industry to give us the manufacturing muscle, the ordinary man in the street, would never be able to enjoy such motoring miracles at affordable prices. We are attempting to do the same for the yachting world.

BUNKERING: FILLING THE TANKS UP

As we write, there are very few dockside bunkering facilities around the world, meaning that crossing the Atlantic would need more than a few hydrogen tube trucks, or a hydrogen container to be provided at a dockside, on a temporary basis.

What we have is a chicken and egg situation, where the Elizabeth Swann, is a cart before the horse. But a cart that may help the current push for more hydrogen bunkering. Without port facilities in place, fleet operators are unlikely to invest, to commission conversions or new builds.

Fortunately, we have solar panels onboard, that can be engaged at any time, such as for the return journey. Meaning, that we can afford to be hydrogen ship waiting for bunker facilities.

If and as preferred, the Atlantic can wait while we set a record across the Pacific. E.g. from San Francisco to Hawaii. The order does not matter, so long as we achieve our goals. The logical order is Atlantic first for a European launch, Pacific for a US launch and Indian ocean for an Australian launch.

Antwerp has a hydrogen fueling point. Valencia is planning for hydrogen and Rotterdam is creating a European hydrogen hub. Way to go!

ENERGY OBSERVER - Seen here with 34kW of sun packing power, the sprightly 80 foot catamaran still has plenty of life left in her. She has a solar power to hull displacement ratio of 1.14 kW/ton. The Observer can generate hydrogen onboard using an electrolyzer and compressor combo, REXH2, supplied by Toyota, the automotive hydrogen trail blazers. The Observer may not have the capacity to cross the Atlantic on stored hydrogen alone, but is an inspiring example of innovative R&D. Their quoted tank capacity is 332 liters for a total of 62kg of hydrogen, which (according to their information) provides the same energy as 230 liters of fuel (2,218kWh) - compared to a proposed 866kg (29,106kWh) of the Elizabeth Swann. Both vessels manufacture hydrogen onboard from solar pv panels via an electrolyzer, with fuel cells to recombine the gas to make electricity. The Energy Observer's visionary Captain is Victorien Erussard.

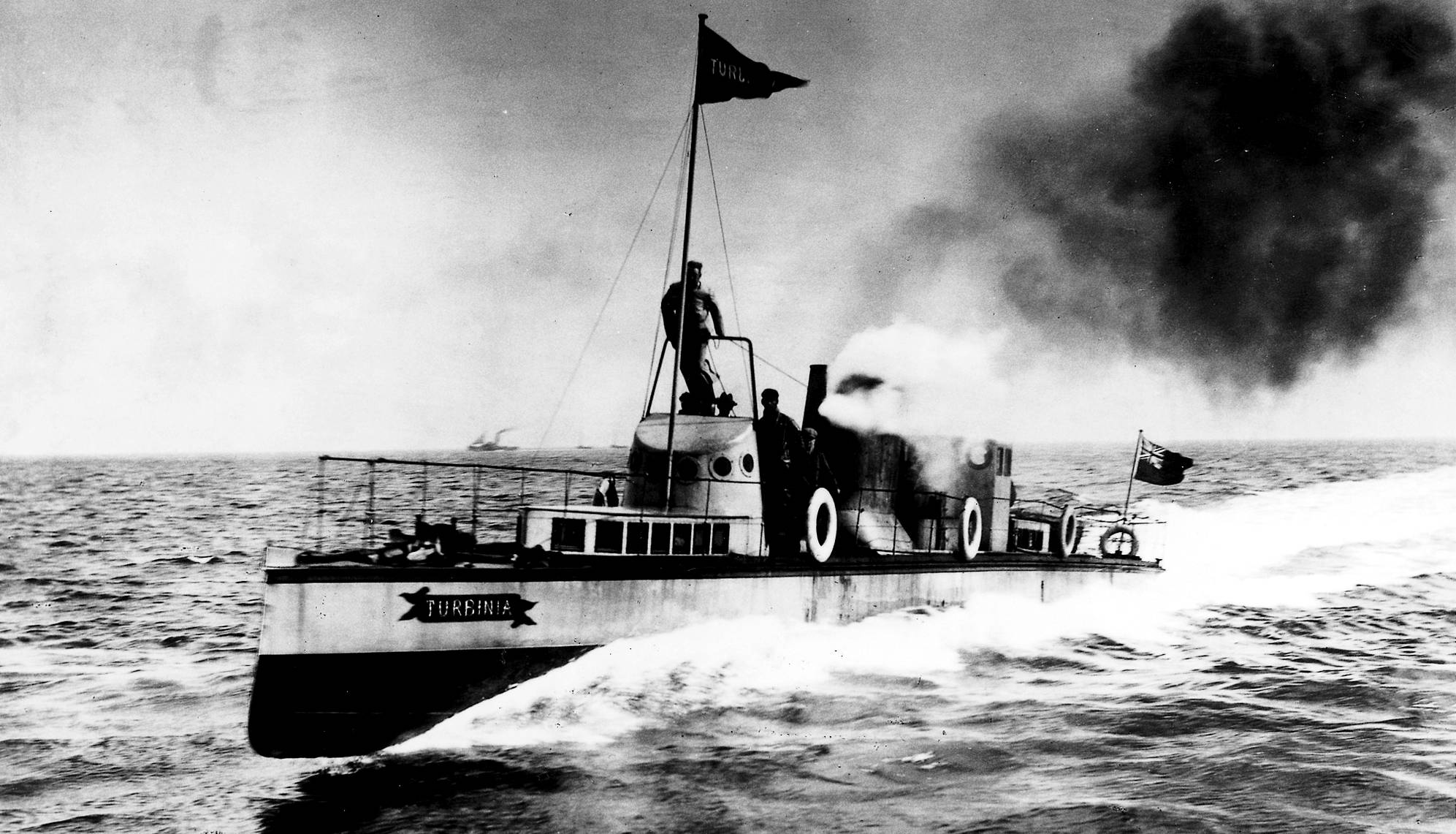

In the naval world, it is often a case of not that it cannot be done, but that the fleet operators, the Admiralty as a case in point, do not like change. Having seen Ericsson's propeller in 1848, the British Navy were content to keep going with paddle steamers. History repeats itself again and again. Having been presented with the steam turbine, it was not until Parson's 'Turbinia' upset Queen Victoria's Spithead Review of 1897, that the Navy sat up and paid attention, and that was only because of the media coverage, where they could not catch his ship, it was so fast.

With these examples firmly in the back of our mind, we are sure that Navies of the world will never give up their nuclear reactors, even with fish being deformed from radiation poisoning, and thermonuclear annihilation an ever present threat to all life on earth.

Cargo fleet operators may only knuckle under, if, as, and when the their competitors are operating with higher profits. The one thing that may help hydrogen ferries and the like, is the IMO's new MARPOL amendments, that are causing quite a stir, with many shipping lines saying that compliance will be impossible. We beg to differ. What may be impossible is for die-hards to develop flexible thinking. The same thing happened changing from sail to paddle steamers.

In October 2020, the IMO did not reach an agreement around a CO2 reduction roadmap for shipping. However, the EU Parliament has voted to include shipping into its Emission Trading Scheme (ETS) from 2022 onwards.

[LEFT] TURBINIA - Parsons' ship turned up unannounced at the Navy Review for Queen Victoria's Diamond Jubilee at Spithead, on 26 June 1897, in front of the Prince of Wales, Lords of the Admiralty and foreign dignitaries. As an audacious publicity stunt, Turbinia, which was much faster than any ship at the time, raced between the two lines of navy ships and steamed up and down in front of the crowd and princes, while easily evading a Navy picket boat that tried to pursue her, almost swamping it with her wake. The first turbine-powered merchant vessel, the Clyde steamer 'TS King Edward,' followed in 1901. The Admiralty confirmed in 1905 that all future Royal Navy vessels were to be turbine-powered, and in 1906 the first turbine-powered battleship, the revolutionary 'HMS Dreadnought,' was launched.

[RIGHT] MARINE CHRONOMETER - The Board of Longitude, famously, charged with finding a solution to the navigation problem, failed to recognize when they had found what they were looking for. This is a frequent problem for experts who only want to receive solutions that fit within their understanding of current knowledge - not accepting anything that does not conform. They would rather deny a solution. Some more practical sailors thought otherwise, gratefully accepting John Harrison's timepieces as essential navigation aids. This included the Royal Navy's Captain James Cook (HMS Endeavour, Discovery & Resolution) and Captain Robert Fitzroy (HMS Beagle) 1763-1779. Modern day 'Board's of Longitude,' are seen in technology grant decision makers all over the world. They fight shy of presented solutions, they want alternative solutions. It keeps them searching for their Unicorns and creates new knowledge. Such policies are though climate unfriendly in a race against time. A climate friendly policy is one that gets results more quickly and with the minimum of administration, such that the Harisson's and Ericsson's might surface sooner. If you have to keep on and on issuing calls for proposals, that extends the time to a solution that we can ill afford. Better, perhaps, to support the bird in the hand. If development takes longer and costs more, don't forget that money also equals a bigger carbon footprint, in the form of the taxpayer who earned the money for the grant-maker's to spend.

A BIT ABOUT HYDROGEN

One liter of

hydrogen gas weighs only 90 mg under normal atmospheric pressure. It is 11 times lighter than the air we breathe.

Atmospheric pressure is roughly 14.6959 pounds per square inch. Also called barometric pressure. The 'atm' unit is roughly equivalent to the mean sea-level atmospheric pressure on Earth.

* Charging from solar panels @ 70kW for 10 hours/day, could fill the tanks to 70 bars in around 46 days in dock @ 60%, allowing for electrolyzer losses (40%). Or, to 140 bars in 92 days. Hence, the losses, including running the hydrogen back through a PEM fuel cell @ 50% efficiency, is significant - meaning we only get 30% out of the energy coming in from the sun - best case. This is a good argument for a battery/solar hybrid setup, even in commercial vessels where the fleet operators want fill and go convenience.

|

|

ZEWT ALORS - The solar and wind powered 'Elizabeth Swann' will feature solar collectors and wind energy harvesting apparatus in an advanced configuration. Her hull configuration is ideal for mass hydrogen storage tanks, offering ranges of up to 4,000nm.

|

|

A central wave piercing hull stabilized by outriggers as a trimaran including:

a) Ultra light superstructure purposed designed to harvest energy from nature via b) and c) below,

b) Solar wings that track the sun and fold for storms, in concert with

c) A turbine generator on a mast that tracks wind conditions and furls for storms.

The theoretical displacement we are working towards is: 30,000 - 45,000 kilograms (target) in 5083 marine grade alloy.

A-Z

INDEX OF H2 POWERED FUEL

CELL SHIPS

A-Z FERRY OPERATORS & ISLAND SERVICES

DFDS -

LINKS & REFERENCE

http://

|

|

Please use our A-Z INDEX to navigate this site or return HOME

This website is Copyright © 2021 Jameson Hunter Ltd

|